- Legal compliance TAIYO YUDEN shall observe and comply with legal obligation on product safety such as Consumer Product Safety Act.

- Responding to customer requests TAIYO YUDEN shall accurately grasp customer requests on quality and product safety and make best effort to respond such requests. TAIYO YUDEN shall proactively collect, understand and analyze quality information in customer application and market, and provide proper quality information.

- Quality management system based on preventive action In order to ensure quality and product safety, TAIYO YUDEN shall perform quality control based on effective and preventive activity, and strive for maintaining control level and continuous improvement.

- Contingency plan on product safety In case of accident on safety due to TAIYO YUDEN product, TAIYO YUDEN shall, according to contingency plan on product safety, take prompt action to minimize damage.

Quality Assurance Activity

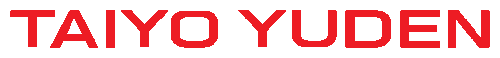

Statement on Quality and Product Safety

TAIYO YUDEN CO., LTD. and its affiliates and subsidiaries (hereafter called "TAIYO YUDEN") considers that ensuring quality and product safety of product which is designed, developed, produced, or sold by TAIYO YUDEN is utmost management issue, and shall observe this statement, and ensure quality and product safety in order to make persistent supply of product with customer satisfaction to worldwide market.

Katsuya Sase

Representative Director,

President and Chief Executive Officer

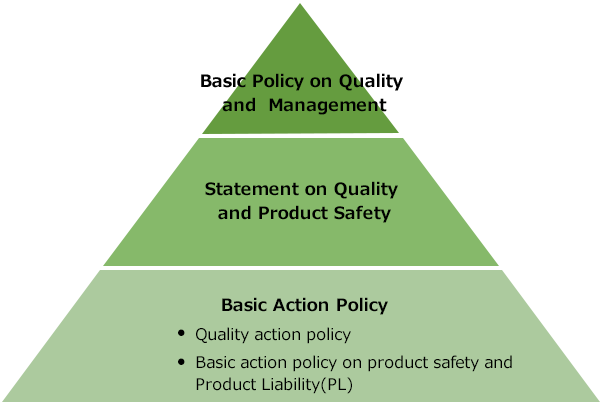

Quality Assurance System of TAIYO YUDEN

System on Quality Assurance

TAIYO YUDEN shall vertically and horizontally manage quality assurance system.

Each division has established quality assurance department and it shall manage domestic and overseas production bases. Quality assurance headquarter shall manage all divisions. Thus, TAIYO YUDEN shall realize close information exchanges among all divisions.

Quality information collected from internal and external sources shall be assessed properly and utilized for preventing quality incidents, its recurrence/expansion. TAIYO YUDEN shall have systems for critical quality information to be reported promptly and accurately to CEO, and CEO shall make a management decision.

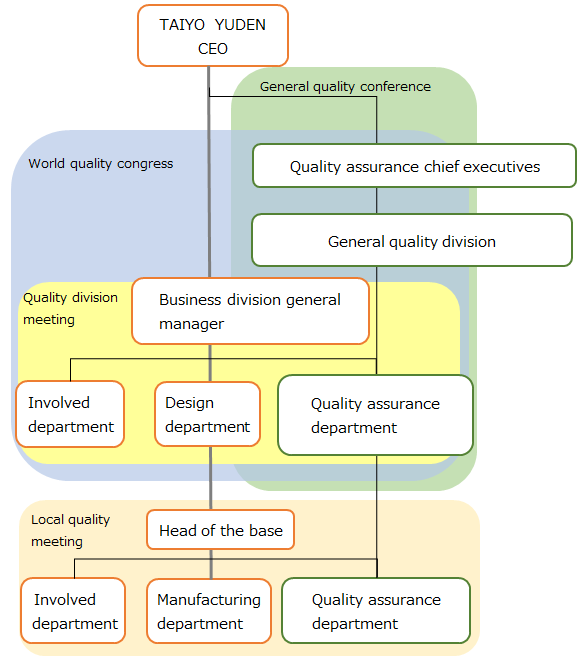

Quality Assurance Activity

【Audit quality assurance activity】

Before the outbreak of COVID-19, Quality assurance headquarter annually audited all production bases, and confirm that the management methodology common to all groups is operated accurately at the same level. In addition, quality assurance departments of all divisions conducted “quality system audit”, “process audit”, and “quality audit” at least once per year, and maintained the status that the processes are operated properly.

Under the influences of COVID-19, domestic and international travel is restricted. However, each production base implements in-house audit and maintains the status of all the processes being operated appropriately.

【Share quality information and expansion】

The chief manager of the quality assurance headquarter shall organize monthly remote conference for all quality representatives of all divisions to attend. They shall share quality information of each division, spread their improvement in control method, and do activities to enhance the quality standard of the whole group. In addition, the representatives in quality assurance departments of all domestic and overseas production bases shall be informed of the quality policies and the efforts of the head office through remote conference. Thus, the activities to guarantee quality shall be securely conducted.

【Ensure product safety】

As for develop assessments of products with high risks of product safety, TAIYO YUDEN shall conduct assessments of safety impact 100% and make best effort to ensure product safety.

In addition, all executive officers, who are in charge of all divisions, shall take a course on PL once a year, and they have the occasion to recognize again that ensuring product safety is utmost issue. Thus, TAIYO YUDEN shall try to ensure the product safety.

【Enhance awareness】

The employees at the supervisory position must pass QC test, and we shall try to enhance our knowledge level through ten kinds of in-house trainings concerning quality implemented by Quality assurance headquarters. We shall invite external lecturers and have them give quality seminar once a year to enhance awareness of the employees.

Quality Risk Management

For the purpose of managing customer information, promptly detect serious quality safety problems and prevent recurrence of the same kind of problems, TAIYO YUDEN has established "PL operation provisions".

In order to report serious quality problems to chief executives promptly and correctly, TAIYO YUDEN has established "standards on product safety management" and "initial response to complaints on automotive products".

While responding to the customers promptly, the quality assurance headquarter and quality assurance departments of all divisions, in collaboration with each involved department, shall strive for prompt complaints detection, and prevention of future occurrence or recurrence.

TAIYO YUDEN has established “Operational provision on Product Liability (PL)”, in which specific activities related to each department are provided on the four items below. According to them, we shall prevent Product Liability (PL) incidents, which cause damage to our customers' life and property due to using the products which are produced and sold by TAIYO YUDEN. Thus, we shall provide highly safe products.

- Activities for ensuring product safety

- Activities for handling PL incidents and preventing expansion and recurrence

- Activities for preventing PL risks

- Activities for enlightening and advertising PLP, and site audit on PLP activities status

Status of Observing Regulations and Voluntary Specifications on Product Safety

| Index | Goal | Actual Performance | ||

|---|---|---|---|---|

| FY2020 | FY2021 | FY2022 | ||

| The number of serious product incident*1 | 0 | 0 | 0 | 0 |

| The number of serious violations of laws and regulations*2 | 0 | 0 | 0 | 0 |