From windshield wipers and power windows to the basic functions of run, turn, and stop, all the mechanisms in vehicles today are precision controlled by advanced on-board computers. Additionally, recent years have seen the adoption of advanced driver assistance systems (ADAS), which take advantage of state-of-the-art information processing technology. And in the near future, it is projected that markets will progress towards autonomous vehicles and software defined vehicles (SDV), which use software to achieve high-value-added vehicle functions.

With advancements in electrification and electronic controls, modern vehicles, which are often referred to as “computers on wheels,” evolve to become “mobile data centers.” This evolution is what will likely lead to the integration of high-performance on-board computers, networking equipment, and other vehicle electronics that are driven by motors with higher output than have ever been used before.

Generally speaking, such advancements in the functionality of vehicle electronics tends to involve massive power consumption. As such, this also means there is a need for power circuits capable of higher efficiency and more stable power provision. However, we have reached a point where the electronic components comprising existing power circuits are no longer capable of fully meeting the technological parameters demanded by next-generation vehicles. This evolution in vehicles is creating the need for technical innovation for the electronic components used in the power circuits of vehicle electronics.

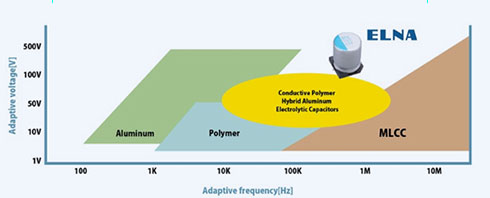

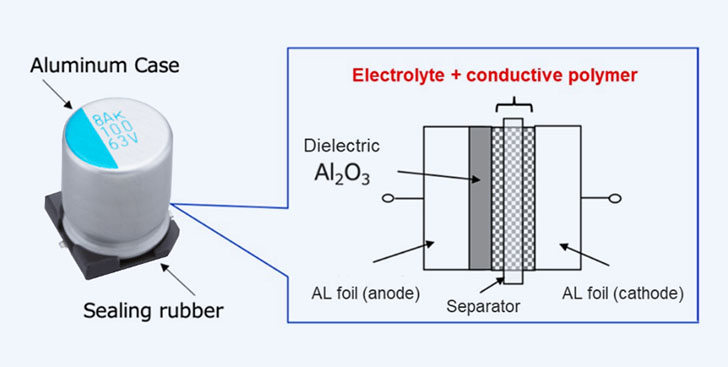

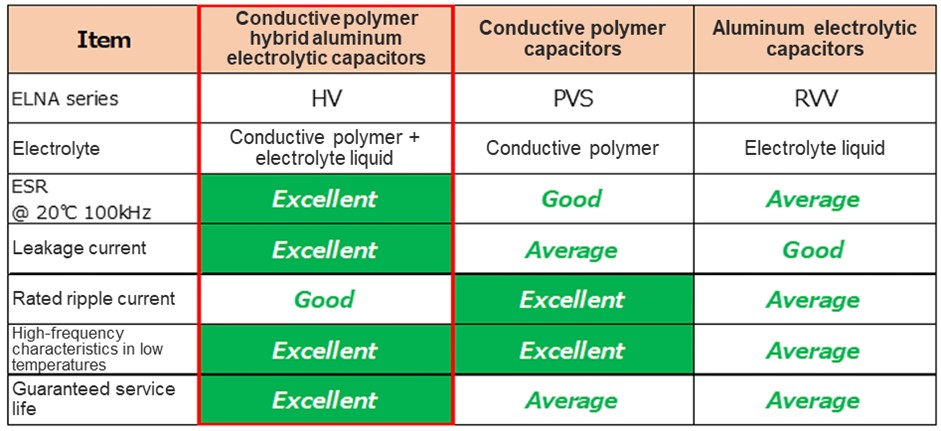

“We have expanded our line of new conductive polymer hybrid aluminum electrolytic capacitors (below, hybrid capacitors) to contribute to higher reliability, longer service life, greater efficiency, and smaller sizes for the power circuits providing compatibility for the increasing power needs of vehicle electronics,” says Tadahiro Nakamura of ELNA, a subsidiary of TAIYO YUDEN.