- TOP >

- Special Feature

Pioneering the Future of Ultra-small, High-capacitance, High-voltage-resistant MLCCs

-

-

Ubiquitous in electronics and electric devices, MLCCs continue to generate volume growth

TAIYO YUDEN’s core MLCCs are a class of electronic components used in all common electric and battery-run devices, including mobile devices, household appliances and automobiles.

Capacitors are used in electronic circuits for temporary storage of electric charges and for noise suppression that eliminates unnecessary signals. Capacitors vary based on materials, design structures, and other factors. While there are different types of capacitors such as electrolytic capacitors and film capacitors, MLCCs are the most common and are constructed with alternating extremely fine ceramic dielectric and electrode layers.

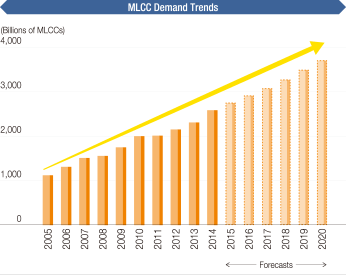

With global annual shipments of MLCCs currently estimated at 2.5 trillion units, this market is worth ¥650-700 billion annually and continues to grow rapidly. Demand for electronics and electrical devices with higher performance and greater functionality is creating the need for an increasing number of capacitors in each end-product.

-

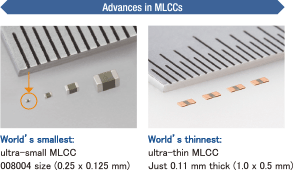

For example, in 2006, high-end mobile phones contained about 300 MLCCs when they started being equipped with camera and TV functions. Today, however, compact, multifunction smartphones use as many as 600 to 800 MLCCs per handset. In that time, MLCCs have become smaller with higher capacitance. This was done to meet the need to have a large number of capacitors in a very limited space with greater functionality.

In our focus markets of automobile electronics, industrial equipment, medical and healthcare, environmental and energy, high-quality and high-reliability products are required amid the growing needs for high functionality and high value-added features.

-

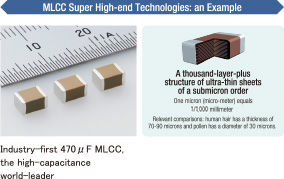

Our super high-end product strategy leverages our state of the art technological capabilities

Of TAIYO YUDEN’s fifteen “super high-end products,” five types of MLCCs are categorized as super high-end products. We have leveraged our high-level technological capabilities and brought these super high-end products first to the market in mass production and we are leading the market with new product introductions. We will continue to expand the super high-end product lineup and plan to add product lines. This is consistent with our strategy to introduce the next high-end product lines, which will add significant value for our company and its stakeholders.

Definition of a super high-end product

- Product that obtains the top position in the global market

- Product that only 2.5 suppliers can develop in the field

- Product that provides solutions for growth markets

- Products that sustains a strong competitive edge

-

Our capacitor business has three distinctive elements

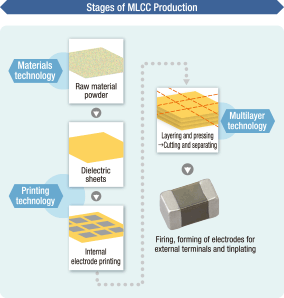

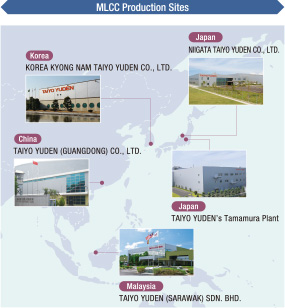

TAIYO YUDEN’s capacitor business has three distinctive elements. First, we are one of very few makers of capacitors that create our products from the ground up—from developing raw materials onwards. Second, our highly advanced precision printing and multi-layering technologies, along with our materials technologies, give us the ability to consistently produce industry-leading ultra-small, ultra-thin, ultra-high-capacitance products. The third element is our global production structure in Japan (Niigata and Gunma prefectures), Malaysia, China, and Korea, that gives us an optimal manufacturing solution and a highly stable supply system. We constantly aim to be No. 1 in the market by harnessing these strengths and by applying super high-end technologies to realize ultra-small, ultra-thin, ultra-high capacitance products.

-

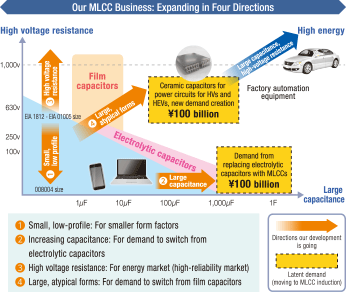

Global MLCC sales volume is projected to approach 4 trillion units annually by 2020. As mobile devices continue to become smaller with more sophisticated functions, capacitors will also need to become smaller while providing higher capacitance. The increasing use of electronics in automobiles and industrial equipment will also increase demand for highly reliable products. MLCCs are ideally suited to meet these demands. They deliver superior compactness and thinness versus electrolytic capacitors and film capacitors, and they provide high reliability and longer product life.

-

Our strategy for the MLCC business goes beyond growing in line with the MLCC volume growth that is required to realize higher performance for electronics and electric devices. In addition to foreseen market growth, we will also apply our world-leading technological capabilities to actively develop new products and stimulate latent demand by positioning MLCCs to supplant electrolytic and film capacitors. This strategy will create a broader demand base for our MLCC products and generate new demand.

This website contains forward-looking statements. These forward-looking statements are not guarantees of future performance, and they involve inherent risks and uncertainties.

A variety of factors including changes in the business environment could cause actual results to differ materially from those in the forward-looking statements.

Copyright TAIYO YUDEN CO., LTD All Rights Reserved.