We report how we worked on the 5Ms set in our Medium-Term Occupational Health and Safety Targets, during the fiscal year 2024.

The report covers TAIYO YUDEN CO., LTD.: Six sites, and its domestic and overseas consolidated subsidiaries.

Organizations Covered by this Report

| TAIYO YUDEN CO., LTD. (Japan) | Takasaki Global Center / Haruna Plant / Nakanojo Plant / Tamamura Plant / Yawatabara Plant / R&D Center |

|---|---|

| Consolidated Subsidiary (Japan) | TAIYO YUDEN CHEMICAL TECHNOLOGY CO., LTD. / TAIYO YUDEN TECHNO SOLUTIONS CO., LTD. / FUKUSHIMA TAIYO YUDEN CO., LTD. / NIIGATA TAIYO YUDEN CO., LTD. / WAKAYAMA TAIYO YUDEN CO., LTD. / TAIYO YUDEN Mobile Technology Co., Ltd. / Kankyo Assist Co., Ltd. / ELNA CO.,LTD. |

| Consolidated Subsidiary (Other Countries) | South Korea:KOREA KYONG NAM TAIYO YUDEN CO., LTD. China: TAIYO YUDEN (CHANGZHOU) CO., LTD. China: TAIYO YUDEN (GUANGDONG) CO., LTD. Philippines: TAIYO YUDEN (PHILIPPINES), INC. Malaysia: TAIYO YUDEN (SARAWAK) SDN. BHD. Malaysia: ELNA (MALAYSIA) SDN. BHD. Thailand: ELNA (THAILAND) CO., LTD. |

Efforts and Status

Man

- Intensive basic training and fostering “Awareness of safe behavior”

- To create a safe workplace culture, we are conducting activities to help employees increase their knowledge of health and safety so that they can perform their work with such knowledge in mind.

In FY2024, we worked on the issues identified on the basis of the results of the analysis of the sixth Safety Awareness Survey of the employees working at the sites in Japan and overseas sites. As a result of conducting basic safety training to make all employees reconfirm the rules to follow, promoting the widespread understanding of the course of action set to enable every employee to ensure their safety, and checking employees’ understanding on a continuous basis, it was confirmed in the seventh Safety Awareness Survey that improvements had been made.

We will continue to conduct the Safety Awareness Survey and improve safety awareness of each employee to promote a culture of workplace safety.

Machine

- Enhancing the level of facility safety design for designers

- With the objective of ensuring our machine safety activities conform to global standards (ISO and IEC), we are reviewing the Safety Standards for Group Machines, which define measures against risks common to production machines to enhance safety measures for them.

In FY2024, we promoted the development of machine designers/persons in charge who have the safety knowledge on safe handling of explosion-proof equipment (SBA-Ex: Safety Basic Assessor in the field of Explosion-proof equipment safety) and reinforced the machine safety system. In addition, we increased the number of machine safety experts (SA: Safety assessor, SSA: Safety Sub Assessor) with the aim of establishing a system to more carefully check machine safety in accordance with the characteristics of each site and have been reinforcing our system continuously.

We will continue our efforts to reduce occupational injuries associated with machines.

Method

- Safe work without inconsistencies

- We are upgrading and reviewing procedures to standardize them and make them safe and consistent so that employees can work more safely.

In FY2024, we improved the workplace safety levels by analyzing the cargo handling operations of loading and unloading, transportation, and receiving and shipping of cargo, verifying and reviewing the risks associated with each operation and measures against them, and standardizing safer methods.

We will continue to strive toward promoting a safe working environment from a common perspective.

Material

- Minimization of toxicity and danger of chemical substances

- To minimize the hazards and dangers of chemical substances, we are continuously taking measures against risks associated with tasks that require workers to handle chemical substances.

In FY2024, we considered and reviewed the risk assessment method for chemical substances and reassessed each task where chemical substances were handled. Based on the reassessment results, we further improved the management of the working environment and tasks to further reduce risks.

We will continue to work toward minimizing the hazards and dangers of chemical substances.

Measurement

- Strengthening of checking system

- To provide safe and hygienic workplaces, we are working to raise check levels by upgrading and improving the methods for identifying invisible hazards (or those that have gone unnoticed).

In FY2024, as for the management of the machine safety measures, measures against risks of falling down while moving around, and other measures, we had the safety and health staff members confirm the effectiveness of the measures and give improvement instructions from a professional perspective. In addition, as a result of standardizing the perspectives and assessment methods used at the sites to check the effects of the measures we focused on and implementing the measures after conducting proper assessments, the workplace safety levels were improved.

Going forward, we will continue our efforts to deepen the level of checks to create safe and hygienic workplaces.

Health

- 1 Reducing incidences of mental health problems

-

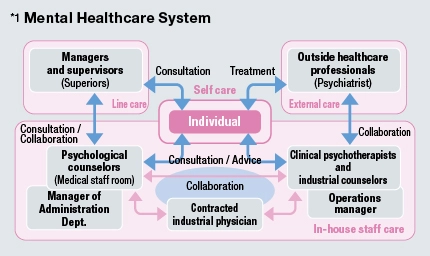

Taiyo Yuden developed a system*1 to reduce the number of employees with mental health problems and are making efforts to prevent mental health problems.

In addition to conducting statutory stress checks using the new Occupational Stress Simple Questionnaire, we also conduct surveys on work engagement*2 and the harassment rate in the organization.

Specifically, as part of the approach to individuals, we made efforts to prevent mental health problems by holding interviews with new employees and mid-career hires whose living environments had changed and employees who were suspected of being at high risk of mental health problems and by conducting the stress check on and recommending counseling to employees assigned overseas. As part of the organizational approach, we provided feedback on the results of the group analysis of the stress check results to the persons in charge of each department and implemented the measures to improve the workplace environment in order to enhance psychological safety,*3 such as the implementation of line care training, efforts to promote communication, and horizontal deployment of best practices.

The incidence rate was 0.78%, a slight increase compared with that of previous year (see G1).

We will continue to enhance training, work closely with industrial physicians, psychiatrists, and industrial counselors, and work on mental health care so that all employees can work with peace of mind and motivation.Mental Healthcare System

G1: Incidence rate

-

*2Work engagement is the condition in which employees gain energy from their work and are proud of the work they do, and so are able to work with vigor.

-

*3Refers to the state where you can speak your thoughts and feelings to anyone in the organization with confidence.

-

- 2 Establishing a healthy lifestyle

-

Under the management philosophy, “Employee Well-Being,” Taiyo Yuden is committed to health management in order to create a foundation for safe and secure work, create an organization where employees work with motivation, and contribute to the improvement of productivity and creativity. To advance these activities, we have set health indicators (Focus 5: food, nonsmoking, exercise, sleep, and stress), established targets, and have been working on specific health measures to achieve these targets.

In FY2024, we implemented measures with a special focus on the sleep of shift workers on which many issues had been identified based on the results of the questionnaire survey of the employees. As shift workers tended to have sleep problems due to their shifts, we held a seminar to enable them to acquire the knowledge necessary to have good sleep even in such an environment and practice what they learned.

As part of the food measures, we conducted vegetable intake measurements to visualize vegetable intake with the aim of enabling employees to review their diet and provided guidance to them based on the measurement results in order to give them opportunities to reconsider their daily diet.

As part of the exercise measures, we provided instructions on proper walking form and held the walking event hosted by the Health Insurance Society just like last year.

In terms of external recognition, we were certified as a Health and Productivity Management Organization 2025 -White 500-*4 and Sports Yell Company 2025*5 for the fifth consecutive year.

We will continue to promote the development of a work environment where our employees can work with vigor while staying healthy both mentally and physically.-

*4The recognition system that evaluates the status of health and productivity management recommended by the Ministry of Economy, Trade and Industry

-

*5The recognition system of the Japan Sports Agency

-