Feature

TAIYO YUDEN Value Creation

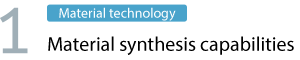

Product Development Centered on

Material & Multilayer Technologies

TAIYO YUDEN has cultivated various technologies over the course of developing and manufacturing its mainstay capacitor products since its foundation. These key technologies are used in other TAIYO YUDEN products and new fields and, in turn, are supporting the growth of the TAIYO YUDEN Group.

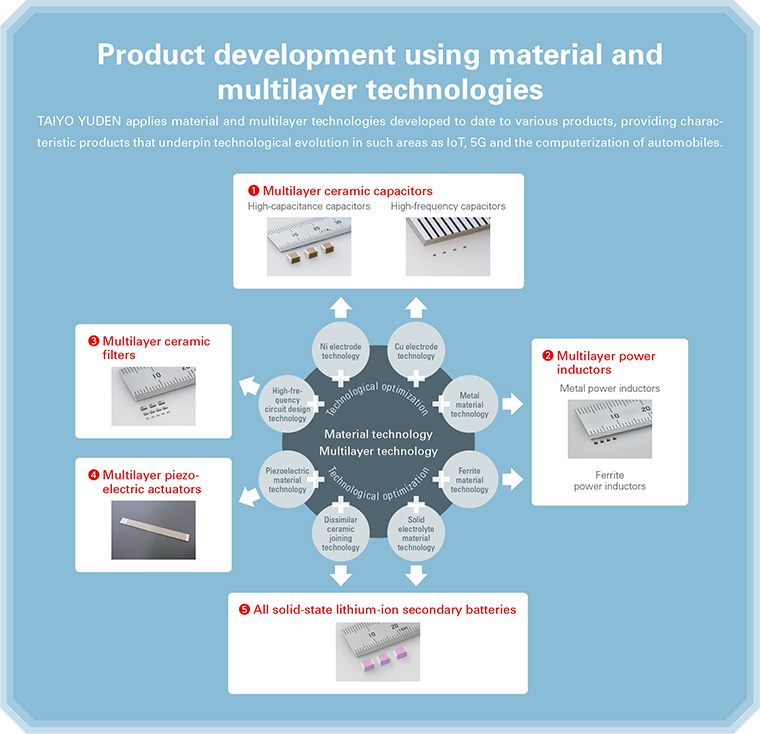

TAIYO YUDEN Core Technologies

TAIYO YUDEN has cultivated many important core technologies over the course of developing various products to date. We continue to provide products that meet customer needs through optimal combinations of these technologies. The characteristics of multilayer ceramic capacitors (MLCCs) in particular depend greatly on the performance of materials. Consequently, TAIYO YUDEN has created a consistent in-house production system extending from materials development to production, and this has enabled the Company to maintain its competitive edge. Ceramic materials with superior properties are a baseline element vital for continuing to develop cutting-edge products, and we use a wide range of technologies freely for raw material synthesis and particle control.

Beyond materials development, we aim to increase the sophistication of various technologies used at each stage of the manufacturing process. Multilayer and other process technologies are critical for determining product performance and have become key themes for our research and development activities.

-

Material technologies

Powder surface coating technology, interface control technology, ceramic material technology (dielectric, magnetic, piezoelectric, insulating), organic materials, electrode materials, metallic magnetic materials, electrochemical materials, ionic conductors

-

Production system technologies

High-speed, high-precision component carrier and supply technology, production system control technology, image processing technology, assemble technology, production engineering technology, maintenance technology

-

Processing technologies

Powder handling technology, thin film technology, green sheet thinning technology, printing technology, lamination technology, forming technology, firing technology

-

Evaluation technologies

Measurement and evaluation technologies (material, process, product, manufacturing equipment, quality and reliability), analysis technology, EMC technology, simulation technology (physical, electrical and mechanical characteristics), quality and reliability control technology, safety standard technology

-

Mounting technologies

PCB technology (fine patterning, precise trimming), mounting technology (Flip Chip Bonding and wire bonding…), termination technology, cleansing technology, resin technology, packaging technology

-

Engineering technologies

Material engineering technology, component engineering technology, circuit design technology (power supply/high frequency), structural design technology, manufacturing equipment design technology, quality and reliability control technology, safety standard technology

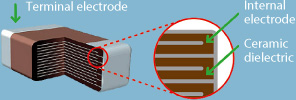

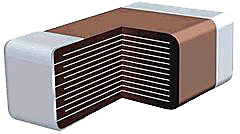

MLCC structure

MLCCs use a multilayer structure that consists of alternately stacked ceramic dielectric layers ("dielectric layers") and electrode layers. MLCC electricity storage performance is determined by the surface area of internal electrodes, so forming thin layers and using a multilayer design is necessary for storing large volumes of electricity within a small size.

TAIYO YUDEN Material & Multilayer Technologies that Realize High-quality MLCCs

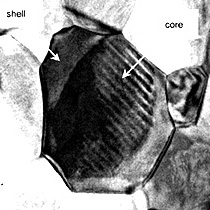

Barium titanate is a MLCC dielectric material made by combining titanium oxide with barium carbonate. TAIYO YUDEN possesses technologies for synthesizing internally optimal barium titanate tailored to product characteristics.

Barium titanate core shell structure

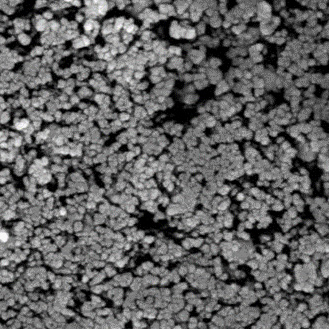

Barium titanate particle that is uniform in shape and size is extremely important for realizing desirable characteristics. Barium titanate particles are small at just around 15nm, and we have technologies that can maintain uniform control at even such a small particle size.

Ultrafine powder

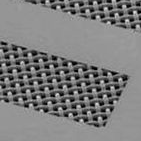

MLCCs are made by printing electrodes on to thin dielectric layers, which are then layered together. As products are very small*, even a slight printing flaw will result in product defects. TAIYO YUDEN undertakes high-precision printing using technologies that prevent oozing and blurring in printing.

* The smallest TAIYO YUDEN product is 0201 size (0.25mm×0.125mm×0.125mm)

Printing-use high-precision screen mask (enlarged view)

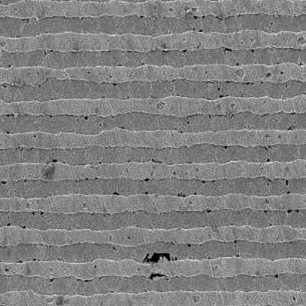

A single MLCC layer is thin at just around 300nm. The layering of many thin layers enables MLCCs to store a greater volume of electricity, so technology that layers thin sheets without deviation has become extremely important. TAIYO YUDEN has enhanced the sophistication of this multilayer technology, offering products with multilayer structures of 1,000 layers or more.

MLCC cross-section (dielectric layers are darker, electrode layers are lighter)

1.Multilayer ceramic capacitors (MLCCs)

What type of product is this?

MLCCs help store electricity temporarily, maintain stable voltage, and eliminate noise in electronic components installed all types of electronic devices found everywhere. TAIYO YUDEN offers a wide-ranging lineup of compact, thin and highly reliable MLCCs that feature high-capacitance owing to its material-based development capabilities.

What is the market environment like?

Electronic devices are progressively becoming more compact and high functioning. Accordingly, installed MLCCs need to be smaller and have higher-capacitance, while the number of MLCCs per electronic device is increasing.

For example, smartphones are becoming thinner and more functional, which in turn is creating a particularly strong need for even smaller components. Electrostatic capacitance and rated voltage decrease as the MLCC size becomes smaller, so improving these features have enabled more compact MLCCs.

In addition, the computerization of automobiles has progressed in recent years, requiring MLCCs installed in these electronic circuits to have more compact designs/higher-capacitance as well as be highly reliable.

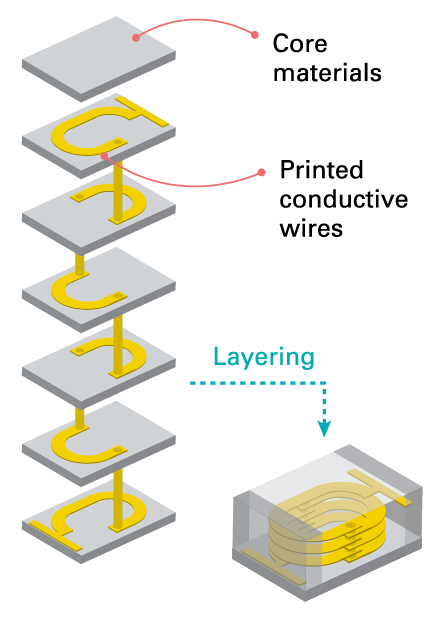

2.Multilayer-type metal power inductors

What type of product is this?

Inductors are mainly used to stabilize voltage and align electric signals in electronic circuits. The structure of inductors consists of wire-wound and multilayer types, with the latter facilitating smaller and thinner designs. In addition, the use of metal materials enables inductors to accommodate even larger current. Combining these features, we provide inductors that meet market needs in terms of smaller sizes and larger currents.

What is the market environment like?

IoT-related devices require highly efficient power circuits as they are being operated for long time periods whenever possible. Such devices include smartphones, wearable terminals and sensor networks, all of which have become increasingly high performance and multifunctional. These types of compact/thin devices require small/thin power inductors able to accommodate large current.

3.Multilayer ceramic filters

What type of product is this?

Multilayer ceramic filters are components used to select required frequencies (filtering) across a range from low to high bands based on a structure that combines MLCCs and multilayer inductors.

What is the market environment like?

5G (5th generation mobile communication system) has three characteristics: high speed/capacity, low latency, and numerous simultaneous connections. Accordingly, 5G will be used in even more frequency bands. Multilayer ceramic filters show promise as indispensable components for 5G-compatible smartphones.

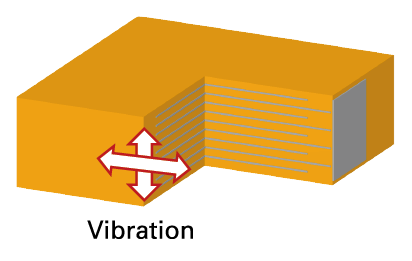

4.Multilayer piezoelectric actuators

What type of product is this?

Multilayer piezoelectric actuators use piezoelectric materials with vibrating properties when added voltage to realize the sensation of pressing buttons on panels along with realizing slick and rough tactile sensations.

What is the market environment like?

Multilayer piezoelectric actuators are installed in onboard vehicle touch panels etc. With the greater use of switch-type flat panels and touch sensors in automobiles recently, tactile impression is required when manipulating switches to ensure safety while driving.

5.All solid-state lithium-ion secondary batteries

What type of product is this?

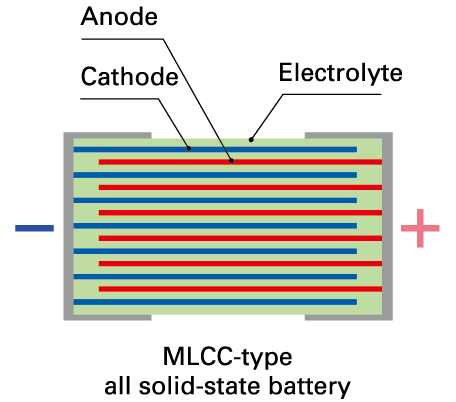

All solid-state batteries developed by TAIYO YUDEN use oxide-based solid electrolytes. The use of solid electrolytes provides superior safety, in principle eliminating concerns over ignition and rupturing. They feature a structure that uses multilayer technology as well as thinner/multilayer electrodes and electrolytes that enable greater electricity capacity, while greater thinness and capacity are both possible.

What is the market environment like?

Batteries with larger capacity are required for IoT, wearable and other mobile devices—all of which look poised to gain in popularity—given the progressive shift to smaller and thinner designs while performance and use duration increase. At the same time, greater safety is needed for wearable devices in terms of preventing battery ignition or aberrant heating. To this end, development has picked up for all solid-state batteries installed in such devices that are required to be compact, have large capacity and feature greater safety.