Operation Principle of Metal Supported - Solid Oxide Fuel Cell (MS-SOFC)

-

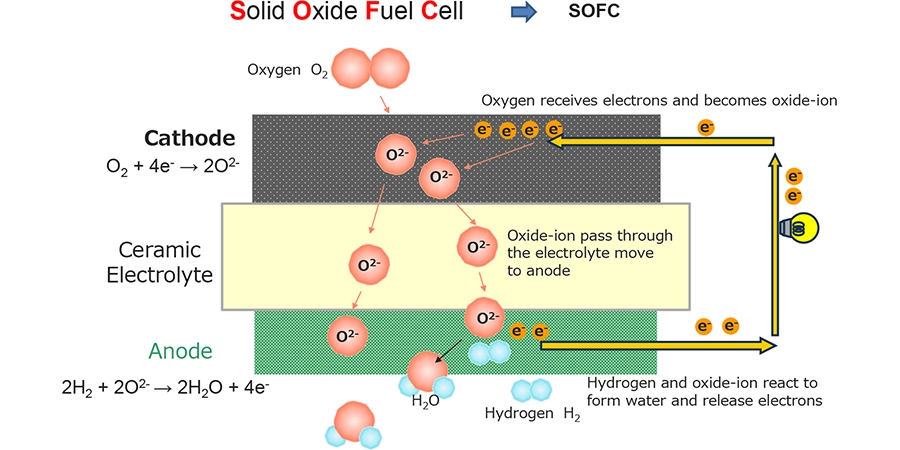

3 layer structure of anode, ceramic electrolyte, and cathode

-

Oxygen at the cathode receives electrons and becomes oxide-ion

-

Oxide-ion pass through the ceramic electrolyte and move to the anode

-

Hydrogen and oxide-ion react at the anode to form water and release electrons

-

The electrons move through the external circuit and an electric current flows

Advantages & Features

A Simple Stack Design

-

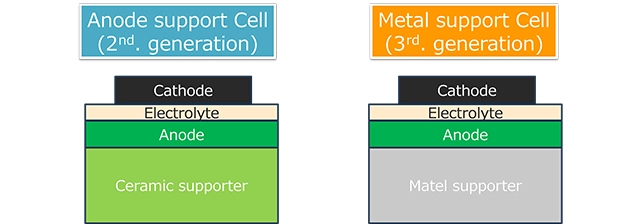

Fast start-up and thermal cycling

-

The mechanical properties are significantly improved by supporting with metal (stainless)

-

Expected to lower the cost

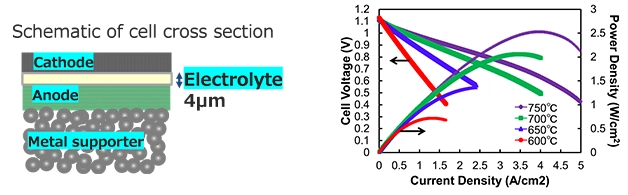

Ultrathin Electrolyte Layer of 4 μm

-

High power generation performance of over 0.7 W/㎠ in the medium temperature range of 600℃ to 750℃.

-

The thickness of the electrolyte has been reduced to 4 μm by utilizing thin-layer technology of MLCC.

Customizable up to a Maximum Size of □100 mm

Less micro-cracks in electrolyte layer and loss due to gas leak is lower than 1.1%

-

*OCV: Open Circuit Voltage

| 600℃ | 650℃ | 700℃ | 750℃ | |

|---|---|---|---|---|

| Theoretical OCV(V) | 1.163 | 1.156 | 1.149 | 1.142 |

| Measured OCV(V) | 1.154 | 1.146 | 1.139 | 1.13 |

| Loss | 0.70% | 1.90% | 1.90% | 1.10% |

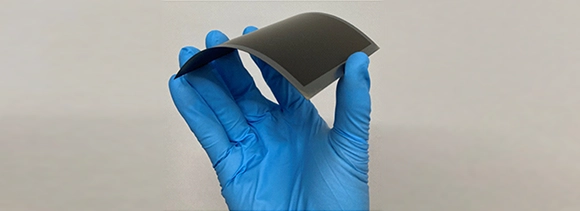

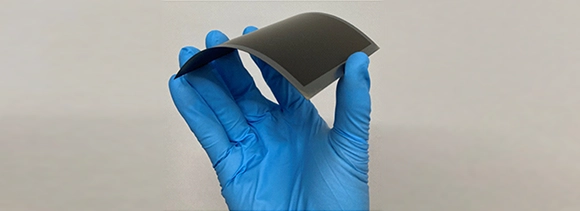

Excellent Handling Characteristics

The excellent handling characteristics of MS-SOFC are expected to reduce the cost of stack design.

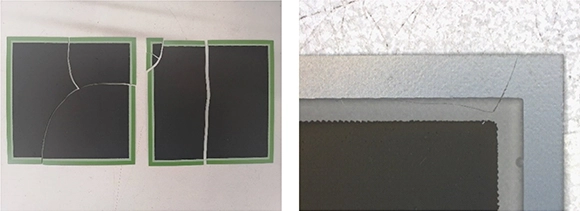

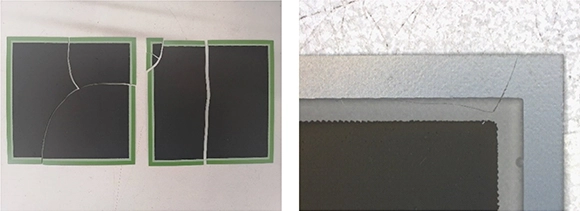

Anode support Cell (2nd, generation)

(left)Break during assembly of power generation experiment(right)Break during experiment

Metal support Cell (3rd. generation)

It is flexible and will not break even when assembled roughly Never broke during experiment

Related Videos

Download Documents

Product Trend / Advantages / Characteristics

Metal-Supported Solid Oxide Fuel Cell (MS-SOFC) with excellent handling and power generation characteristics