The source of our competitive advantage is our technical capability to develop communications devices matched to market needs. Providing leading technology is a way to maintain an key advantage. We will continually challenge ourselves to be the leader in the industry by providing superior communications devices to customers and for use in IC manufacturer reference designs. We will also use our state-of-art technologies, such as the EOMIN™ embedded-parts multilayer wiring substrate, to provide added value solutions, which combine multiple optimal electronic components into modules. We will continue to leverage our strength and position in the market and be the one-stop supplier for customers' needs and exercise our technical capabilities and abundant expertise we have cultivated to present products ideally matched to market needs.

Special feature: Third Pillar “Communications Devices”

-

-

Use of smartphones and other mobile communications devices is rapidly rising throughout the world market in both developed and developing countries. Smartphone ownership is projected* to rise from 12% of the world's population in 2011 to 49% in 2016. TAIYO YUDEN is developing and manufacturing crucial components for mobile communications such as SAW filters, FBAR filters, duplexers, and front-end modules that integrated these functions into compact shapes. The demand for mobile communications devices is growing at an unprecedented rate. These devices are extremely sophisticated and require leading edge technological solutions. TAIYO YUDEN understands this and has the solutions needed to be successful in this market, hence communications devices operation are now the third pillar of TAIYO YUDEN's business.

*Source: Seed Planning “Global Smartphone Proliferation Projection”

Surface acoustic wave (SAW) and film bulk acoustic resonator (FBAR) filters are used in mobile communication terminals to distinguish electric signals of various band frequencies. They, then, filter or pick up transmission signals of specific frequencies. FBAR filters perform better for higher frequencies than SAW filters. A duplexer simultaneously sends signals and filters in-coming signals even when their frequencies are different. These communications devices play an essential role in realizing smooth data communications.

close

-

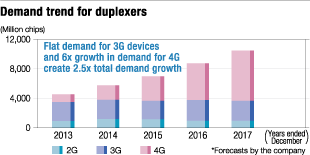

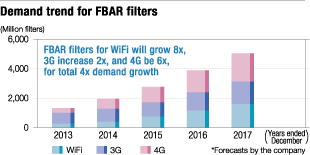

A key focus in this industry is addressing the differences in communications standards and frequency bands among countries and regions throughout the world, which will enable smartphone users to communicate anywhere in the world with a single device at hand. Furthermore, there is a growing volume of communication traffic that requires resolving the use of higher frequencies and closer bandwidths. There are pressing challenges and demand the latest in SAW/FBAR filters and duplexer technology and TAIYO YUDEN is positioned to address these challenges. These conditions now require more than two SAW/FBAR filters and duplexers as a solution. This is needed to support multiple frequency bands and are now mountable in a single smartphone. And, as is the case in our industry, performance demands for the devices continually increases with every new model device being introduced to the market. The volume of mobile data communication is expected to continue growing, and the number of duplexers used in mobile devices is expected to jump 2.5 times from 2013 in 2017 while the number of FBAR filters, which offer superior performance for higher frequency bands, is forecast to grow four times over the same period.

-

Our primary strengths in this market are our expertise in development and manufacturing capabilities for both SAW filters and FBAR filters. We currently are the only company that can provide world-leading technologies for both these product groups.

SAW and FBAR filters are used mainly for different frequency band ranges and have separate manufacturing costs. Having the technologies for both SAW and FBAR filters gives us the ability to be a one-stop supplier of duplexers and communications modules that incorporate the combined technologies of SAW and FBAR filters to meet the customer specifications and demands for qualities and costs. We see this as a huge advantage for the Company.

-

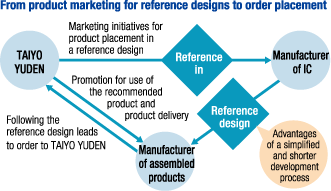

We are formulating strong relationships with smartphone and module makers around the world, collaborating from the early stages of the development of new models to ensure we have a clear understanding of the technical needs and other requirements for the upcoming models. This gives us the ability to develop and offer communications devices that meet market needs. We are also focusing on gaining designations for our products as recommended components in reference designs from integrated circuit (IC) manufacturers who design and develop ICs for mobile communications devices. Mobile communications devices are increasingly required to more rapidly become smaller with higher functionality and lower cost. This is done by incorporating integrated components of smaller and thinner pieces. At the same time, circuit designs are becoming increasingly sophisticated and complex as demand for greater functionality leads to an increasing number of components used in the designs. Smartphone makers are responding by simplifying the processes to reduce costs and product development time. As a result, they are increasingly using reference designs provided by platform IC manufacturers*.

*A platform IC manufacturer independently provides manufacturers of assembled products with platforms that integrate various ICs on single circuit or multiple circuits.

-

In the market for mobile communications devices, we expect the continuing growth of smartphones with a rising number of built-in components, accompanied with a demand for greater functionality. This is the fuel that will drive market growth. To continue growing our sales in the market and to keep pace with demand, we must have an operating structure that enables us to furnish, in a timely manner, a stable supply of leading technology products that meet the customers' needs for quality and pricing.

Therefore, we took a concrete step in that direction with the acquisition of the land and buildings of a former semiconductor factory in Ome, Tokyo. In April 2014, we commenced developing and manufacturing communications devices at the new Ome facility. The facility provides exceptional scalability as it enables us to expand production capacity by 2.5 to 3 times as necessary to respond to future demand. We are reorganizing our production structure to enhance our business efficiency with the Ome Operation Center serving as our primary site for the development and manufacture of communications devices.

-

This website contains forward-looking statements. These forward-looking statements are not guarantees of future performance, and they involve inherent risks and uncertainties.

A variety of factors including changes in the business environment could cause actual results to differ materially from those in the forward-looking statements.

Copyright TAIYO YUDEN CO., LTD All Rights Reserved.