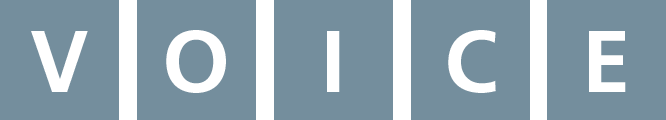

Achieving both social and economic values through uncompromising design and production processes

TAIYO YUDEN upholds a vision of "becoming an excellent company that enjoys the trust and highest regard from all stakeholders." To achieve this, we are determined to ensure an integrated development process from materials to final products while fostering continuous economic growth through innovations in research, development and production. Equally important is responding to social demands and contributing to the resolution of social issues. By aiming to create both economic and social values, we continue our various initiatives to reduce environmental impact during product design and production, ultimately contributing to a safe, secure, comfortable, and convenient lifestyle.

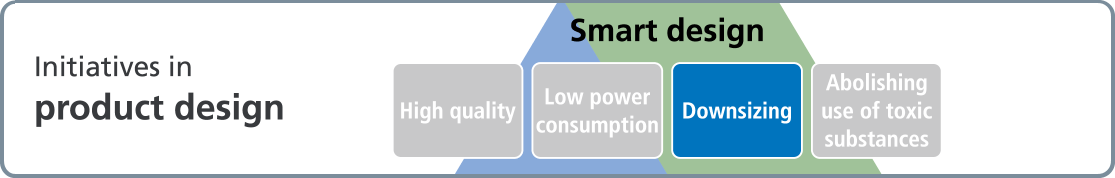

Reducing the environmental impact in product design

We are continuously striving to reduce environmental impact throughout the entire product life cycle by pursuing high quality, lower power consumption, and downsizing our products. In the downsizing process, we leverage a wide range of technologies, including material synthesis and particle control, to deliver cutting-edge products to the market. Additionally, we are committed to developing high-added-value products by actively reducing or banning the use of environmentally harmful substances contained in products.

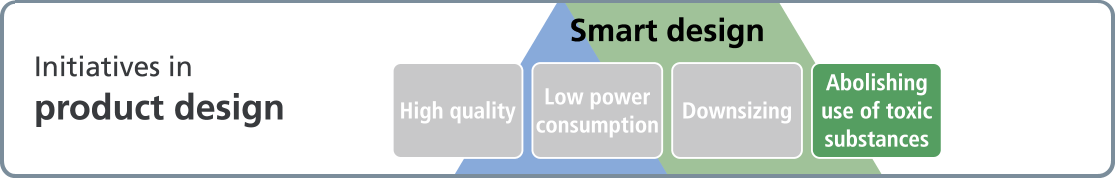

Abolishing the Use of Toxic Substances

As a globally operating company, TAIYO YUDEN constantly monitors the laws and regulations of various countries (including RoHS and REACH), customer demands, and industry standards to identify the latest trends. We utilize these findings to inform our internal standards, actively working to reduce and ban the use of environmentally harmful substances contained in our products.

We believe that addressing chemicals in products (CiP) is our responsibility towards creating a sustainable society, which will, therefore, enhance our competitive advantage. In addition to providing legal compliance, we will continue striving to improve both customer satisfaction and environmental protection, consistently producing high-quality products as the industry's leading company.

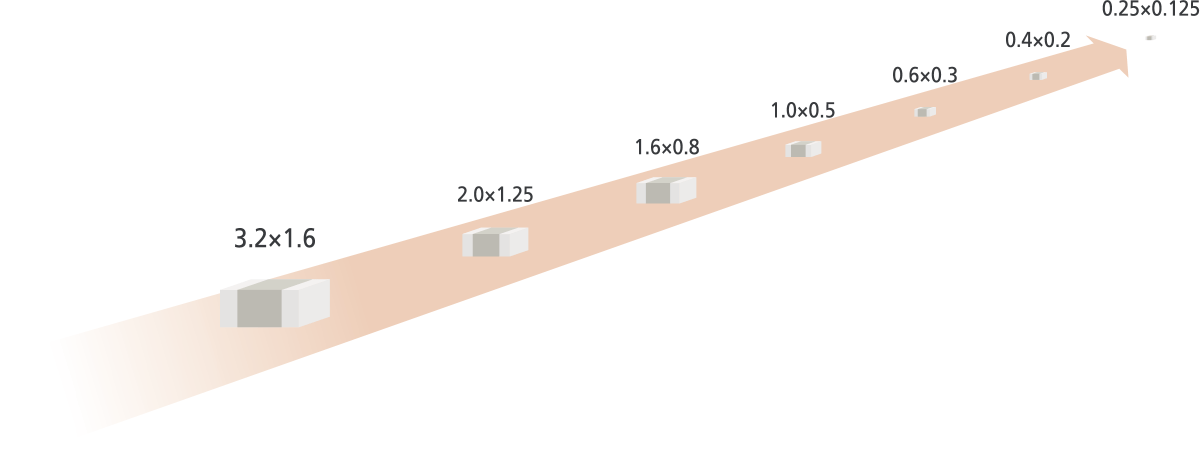

Evolution of Product Downsizing

By advancing product downsizing, we can reduce not only the amount of raw and packaging materials used but also the energy required during manufacturing. For example, in the production of multilayer ceramic capacitors (MLCCs), a significant amount of energy is consumed during the firing process, where ceramic and internal electrodes are integrated by firing them at high temperatures. However, downsizing allows us to shorten the firing time or increase the number of units per firing furnace, leading to a reduction in energy consumption.

Technology That Enables Product Downsizing

TAIYO YUDEN has secured a competitive advantage by establishing an integrated production system that handles everything in-house, from material development to final product manufacturing. By utilizing various technologies, such as raw material synthesis and particle control, we develop high-performance ceramic materials that form the foundation for the continuous development of cutting-edge products. Additionally, we achieve downsizing through uniform printing technology and advanced multilayer technology.

Material synthesis technology

Barium titanate is a MLCC dielectric material made by combining titanium oxide with barium carbonate. TAIYO YUDEN possesses technologies for synthesizing internally optimal barium titanate tailored to product characteristics.

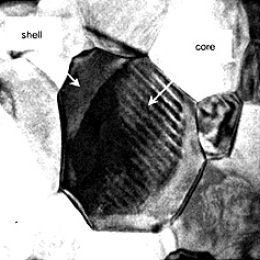

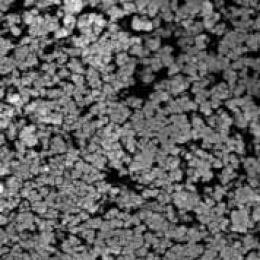

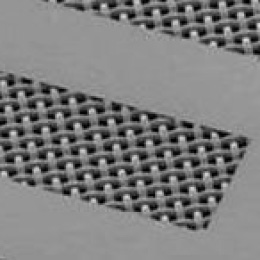

Particle control technology

Barium titanate particle that is uniform in shape and size is extremely important for realizing desirable characteristics. Barium titanate particles are small at just around 15nm, and we have technologies that can maintain uniform control at even such a small particle size.

Uniform printing technology

MLCCs are made by printing electrodes on to thin dielectric layers, which are then layered together. As products are very small, even a slight printing flaw will result in product defects. TAIYO YUDEN undertakes high-precision printing using technologies that prevent oozing and blurring in printing.

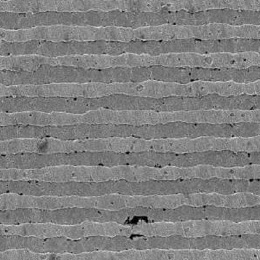

Accurate layering technology

A single MLCC layer is thin at just around 300nm. The layering of many thin layers enables MLCCs to store a greater volume of electricity, so technology that layers thin sheets without deviation has become extremely important. TAIYO YUDEN has enhanced the sophistication of this multilayer technology, offering products with multilayer structures of 1,000 layers or more.

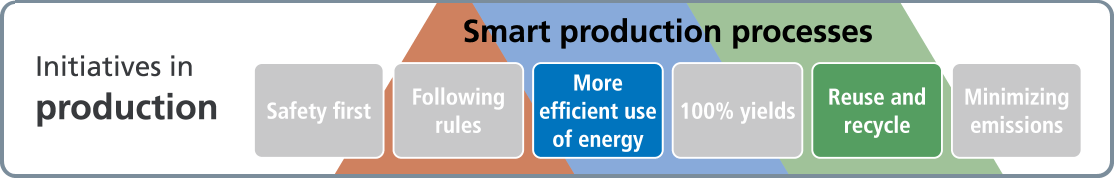

Reducing the environmental impact of production

With employee safety as our top priority, we implement manufacturing initiatives that focus on standardized workflows, such as minimizing energy consumption, steadily producing high-quality products, and utilizing waste-free resources. Specifically, we review and upgrade our equipment to enhance energy efficiency while promoting the reuse and recycling of components and materials. By improving productivity, we aim to use resources and energy efficiently, thereby ensuring the stable production of reliable, high-quality products.

Reducing the Energy Loss with the Cogeneration System

We have introduced a cogeneration system that efficiently recovers waste heat generated during power production and effectively utilizes it as energy. The system generates steam from the recovered waste heat, which is then used for air conditioning. This reduces the amount of municipal gas consumed by the existing boilers and decreases CO2 emissions.

Reusing Components and Materials Used in Business Activities

Solvent A, which is the most frequently used solvent in our business activities, is recycled from waste solvent, and regenerated solvent accounts for 42% of its usage.

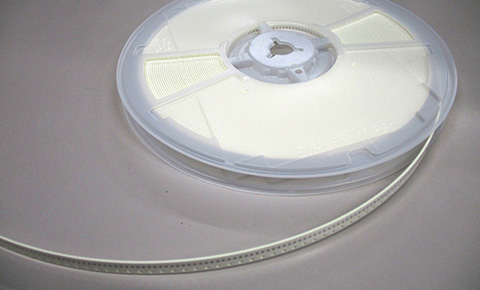

The reels that are used to package electronic components undergo strict quality checks, and 17% of the reels used are reused.

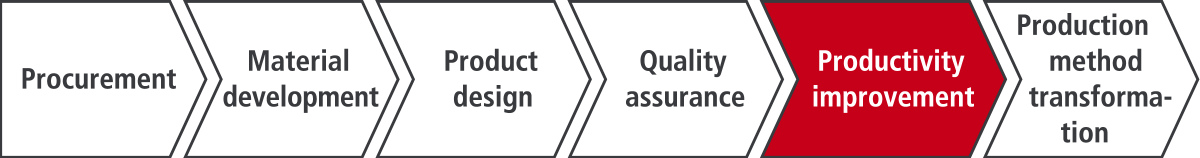

Improving productivity

In parallel with enhancing our capabilities by increasing continuous capital investment, TAIYO YUDEN promotes productivity improvements to drastically raise production output while reducing losses.

We aim to improve yields by eliminating variations among machines and workers to ensure consistent

performance.

Initiatives at WAKAYAMA TAIYO YUDEN

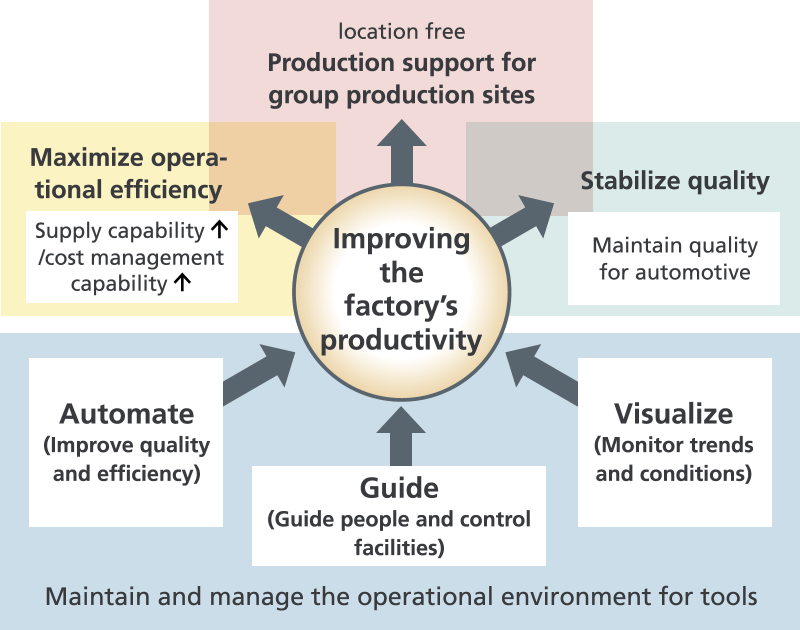

A cutting-edge factory for productivity improvement that supports the Group's production facilities

WAKAYAMA TAIYO YUDEN is enhancing productivity improvements focused on visualization, automation, and guidance, which help maximize operational efficiency and stabilize product quality. In addition, it shares the know-how that it gains with other production facilities within the Group, contributing to productivity improvements across the entire TAIYO YUDEN Group.

Achieving uniform quality and efficient production

We achieve a uniform and efficient production by digitizing and automating manual production tasks while ensuring the effective implementation of 4M (Man, Machine, Material and Method) measures. These efforts have contributed to reducing both the energy consumption per unit of product and the amount of waste generated.

Eliminating management defects through visualization, automation, and guidance

At WAKAYAMA TAIYO YUDEN, we release a new model of the metal power inductor MCOIL™ each year despite the high manufacturing difficulty, leading to an increase in the variety of manufacturing processes and management items. In addition, the frequent changes in task routes and condition settings aimed at improving the production process have made error prevention in these increasingly complex processes a significant challenge. To address this, we have strengthened efforts to visualize and monitor the processes, automate the condition settings, and prevent human errors by guiding workers, which has significantly reduced management defects.

We will continue to advance automation, share our expertise and support other production facilities in and outside Japan, contributing to improved production efficiency across the Group.

WAKAYAMA TAIYO YUDEN CO., LTD.

- Address:

- 4026-22, Inanbara, Inami-cho, Hidaka-gun, Wakayama, Japan

- Number of employees:

- 238 (as of March 31, 2024)

- Production items:

- Metal power inductor MCOIL™